-

All Categories

all-categories

-

H300 Type - Round Outlet Boxes

Cast Iron - Hot Dip Galvanized

Surface Mounting - NEMA 3R - NEMA 4

Unit consists of box, plain cover and gasket. Stainless steel screws. Mounting lugs drilled for 1/4"bolt.

Drilling, or drilling and tapping extra,

Pl0 Pendant cover tapped 1/2"

fits H301 and H302 extra.

P15 Pendant cover tapped 3/4",

fits H301 and H302 extra.

P20 pendant cover, tapped 3/4",

fits H303, H304, H305 extra.

Tapped holes through bosses have five threads.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H400 Type - Square Outlet Boxes

Cast Iron - Hot Dip Galvanized

Surface Mounting - NEMA 3R - NEMA 4

Unit consists of box, plain cover and gasket. Stainless steel screws. Mounting lugs - set of two extra. Set of four extra. Drilling, or drilling and tapping extra.

P70 pendant cover tapped 1/2",

fits H401, H402, H403 - extra.

P80 pendant cover tapped 3/4",

fits H401, H402, H403 - extra.

Bosses required for five threads.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

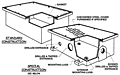

H1200 Type - Unflanged Junction and Pull Box

Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Cast Iron - Hot Dipped Galvanized

Third Party Certification: UL File E 189027

Standard Construction:- Box and plain cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

- Larger boxes have adequate additional screws to insure tightness.

Available Extras:- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Interior mounting buttons tapped blind.

- Special cast covers.

-

H2200 Type - Pull and Junction Box (with overlapping cover)

Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Third Party Certification: UL File E 189027

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Box and overlap cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Interior mounting buttons tapped blind.

H2200 type boxes are equipped with overlapping covers to meet Underwriters requirements on unflanged boxes. They can be safely installed indoors or out-of-doors as the closure of the cover and gasket makes a weatherproof and dust-tight joint.

Conduit entrances should be ordered with bosses of five threads to be rain-tight and dust-tight. Mounting lugs are desirable for out-of-doors installations.

Recommended for enclosing many types of electrical devices as well as junction and pull service. Interior mounting buttons, tapped blind, can be located on specified centers for panels, terminal blocks, cut-outs and like equipment.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H3200 Type - Hinged Weatherproof Box

Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Third Party Certification: UL File E 189027

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Box and plain cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Interior mounting buttons tapped blind for panels or equipment. Hasp without lock.

Featuring a retained one piece gasket with adequate pressure hinges and wing nuts for closure, H3200 type boxes are thoroughly weatherproof and dust-tight.

Conduit entrances should be ordered with bosses for five threads to insure rain-tight and dust-tight installation. Mounting lugs are always desirable for out-of-doors applications.

In addition to general use for junction and pull service, H3200 type boxes make ideal enclosures for (a) cut-outs, (b) transformers, (c) relays, (d) bus bar panels, (e) time signals, etc. Interior mounting buttons tapped blind can be located on specified centers. Complete units of enclosure and equipment by quotation. Terminal block enclosures with 2 to 180 wire systems are available.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H3200-T Type - Hinged Weatherproof Terminal Cabinets

Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Box and cover of cast iron.

- Stainless steel hardware.

- Neoprene gasket.

- Four exterior mounting lugs.

- Terminal blocks mounted on interior buttons or pads. Maximum wire size #10 AWG.

- Drilling only. Drilling and tapping.

- Bosses for five threads.

- Special gaskets.

- Hasp without lock.

H3200-T type terminal cabinets are approved H3200 type enclosures in which substantially constructed terminal blocks are mounted. A variety of sizes for differing wire conditions are listed. The terminal blocks, rated at 30 amperes and 750 volts, are mounted on blind tapped buttons or pads that insure weather tightness and provide an air gap under the block. Each terminal block carries a white-faced target strip for marking connections. Ample wiring space is provided between wall of box and block, and, block to block.

Conduit entrances should be ordered with bosses for five threads to insure raintight and dust-tight installation. Every cabinet can be equipped with a galvanized non-removable hasp to prevent tampering.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H5400 and H5600 Type - Explosion Gutter Boxes

Explosion gutters provide adequate volume for splicing straight through, L or T, as tappings can e on ends, sides or back.All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum.

-

HD5400 and HD5600 Type - Heavy Duty Gutters

Heavy duty gutters are watertight under burial and submersion. They can be supplied with wiping sleeves for lead cables; terminal blocks.

DUSTIGHT - CLASS II

Groups E, F and G when ordered with vellumoid gaskets, "Mechanically attached". Additional Charges. -

H5800 Type - Checkered Cover Sidewalk Box

Flush Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Cast Iron - Hot Dipped Galvanized

Third Party Certification: UL File E 189027

Standard Construction:- Box, flange and cover of cast iron.

- Checkered cover is cross-ribbed.

- Neoprene gasket. Stainless steel fastenings.

- Three piece construction.

- Flanges and covers interchangeable.

- Pry bar notches for lifting.

H5800 type boxes have been widely installed in sidewalks and walkways of bridges, dams, tunnels, approached and airports. The checkered non-slip cover, flush with finished concrete, is cross-ribbed for heavy pedestrian traffic. Flanges and covers are replaceable without disturbing box and conduit system if damaged by truck traffic. For H20 loading, galvanized checkered covers available: Add suffix "SC" to the end of part number to indicate checkered cover.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H6000-Type - Explosion Housing

Surface Mounting

NEMA 4 - NEMA 3R - NEMA 7

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Box and cover of cast iron.

- Two mounting lugs each long side on standard centers. Specify bolt size.

Available Extras:- Drilling and tapping.

- Bosses for five threads to sketch.

- Interior mounting buttons tapped blind.

- Bronze hinges for heavy covers. Having a precision machined surface on flange of box and matching surface on cover, all H6000 Type boxes are NEMA 3R (Raintight) and NEMA IV (Weatherproof) without need for a gasket.

H6000 type explosion housings have been specified and installed in Class I, groups C and D hazardous locations by the larger engineering and erecting companies. Manufactured to the standards of the Underwriters’ Laboratories, Inc., but not tested by them.

Competent specifying engineers have readily recognized the substantial construction of box and cover with the precision finished metal to metal joint as wholly adequate for the use of these boxes for pull and junction service and as enclosures for devices in gasoline refineries, chemical process and powder plants, gas pumping stations and other hazardous locations. Conduit entrances must have five threads. Check wall of box with table in the Ordering Information section. -

HD6000 Type - Heavy Duty Box

Surface Mounting

NEMA 6 - NEMA 4 - NEMA 3R

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Heavy walled box and cover of cast iron.

- Plated steel cap screws.

- Neoprene type packing for gasket.

- Four mounting lugs on standard spacing.

Available Extras:- Drilling and tapping.

- Bosses for five threads.

- Interior mounting buttons tapped blind.

- Special gaskets. Bronze hinges.

HD6000 type heavy duty boxes are heavy walled assemblies substantially gasketed on wide flanges for the most severe types of weathertight and watertight installations.

They are ideal for submersion service and have been successfully installed in flooded manholes, on docks, piers, seawalls, underground and in sub-stations, and will remain watertight under high heads of water.

Protected steel cap screws are standard but monel, bronze or stainless can be supplied. Conduit entrance should be ordered with bosses for five.-threads to insure watertight conduit entry if the wall thickness is less than that required for five threads. Interior mounting buttons located on specified centers and tapped blind for watertightness provide an excellent method for mounting panels, relays, transformers and similar devices.

HD6000 type boxes are acceptable for Class II, Groups E, F, and G hazardous locations when ordered with- Vellumoid gasket – change “Add 8% to list price of box” to “At additional cost”.

- Bossed conduit entrances tapped for five threads.

-

H6200 Type - Internal Recess Flanged Box

Flush Mounting in Concrete or Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Cast Iron - Hot Dipped Galvanized

Third Party Certification: UL File E 189027

Standard Construction:- Box and plain cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

Available Extras:- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Plain brass or checkered bronze covers.

- Hinges. Hasp. Cylinder lock.

-

H6800 Type - Flanged Recessed Cover Topping Box

Surface Mounting

NEMA 6 - NEMA 4 - NEMA 3R

Cast Iron - Hot Dipped Galvanized

Standard Construction:- Checkered non-slip cover is cross-ribbed.

- Three piece construction with neoprene gasket.

- Stainless steel fastenings.

Designed to top off underlying concrete pull boxes. Of substantial construction for heavy foot traffic, they can be supplied with galvanized checkered steel covers for heavy wheel loadings.

Available with cast nodular iron covers (ASTM A536-80) and integral legend by quotation based on quantity.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H7000 Type - Flanged Recessed Cover Box

Flush Mounting in Concrete or Surface Mounting

NEMA 4 - NEMA 3R - Complies with U/L Std. 50

Cast Iron - Hot Dipped Galvanized

Third Party Certification: UL File E 189027

Standard Construction:- Box and plain cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Plain brass or checkered bronze covers.

- Interior mounting buttons tapped blind.

- Galvanized steel checkered cover available if specified by adding the suffix "SC" for "H-5 Pedestrian, or "SCV" for "H-20 Vehicle".

-

H8000 Type - Flat Flanged Box

Surface Mounting

NEMA 6P - NEMA 4X - NEMA 6 - NEMA 4- NEMA 3R

Cast Iron - Hot Dipped Galvanized

Third Party Certification: UL File E 189027

Standard Construction:- Box and plain cover of cast iron.

- Stainless steel machine screws.

- Neoprene gasket.

- Flange and back of cover ground flat before galvanizing.

Available Extras:- Drilling only. Drilling and tapping.

- Bosses for five threads. Special gaskets.

- Mounting lugs.

- Plain brass or checkered bronze covers.

- Interior mounting buttons tapped blind.

H8000 type boxes feature wide flanges that provide ample contact with cover and gasket to insure tightness even under widely varying temperature and climatic changes. Flange widths are graduated from a minimum of three quarters of an inch on small boxes to a width of one and a half inches on large boxes. Screws are properly spaced to make these boxes weathertight under severe natural forces of driving rain, snow, sleet or drippage.

Conduit entrances of five tapped threads for raintight requirements usually require bosses.

Mounting lugs afford easier installation and add sturdiness to the conduit system.

For Class II, Groups E, F and G hazardous locations,

H8000 Type Boxes for class II, (Groups E, F, and G) Hazardous locations

Class II, Groups E, F and G hazardous locations are ones in which explosive mixtures of air with metal dust (Group E), or carbon, coke or coal dust (Group F), or grain dust (Group G), are encountered. Enclosures with adequate flanges, mechanically held gaskets of proper composition, and bossed and tapped conduit entrances with five threads will meet Class II requirements.

All H8000 type boxes listed above will conform to these requirements when ordered specifically as follows:- With gasket of vellumoid: Specify "Mechanically Attached" (Extra 10%)

- With bossed and tapped conduit entrances of five threads Mounting Lugs

- Mounting lugs are optional, but mounting holes through box are not permissible.

See further listing on Class II boxes, under Metal Pipe and Pole Bases and under Explosion Housing.

All boxes that are made in cast iron can also be made in cast aluminum – just add “AL” to the end of the part number to indicate cast aluminum. -

H8200 Type - Hinged-Door and Trim Cabinets

NEMA 4 - NEMA 3R

Flush Mounting

Standard Construction:- Box of cast iron hot galvanized.

- Trim and door of hot galv. cast iron or cast bronze - specify.

- Non-removable hinges. Brass cylinder lock. Weatherproof construction.

- Neoprene and lead gasket.

Available Extras:- Drilling only. Drilling and tapping.

- Bosses for five threads.

- Interior mounting buttons.

- Lettering on door - prices on application.

H8200 type boxes are flush mounted boxes for installation in the public view on concrete or stone structures where an especially attractive finishing box is desired. The trim and door are pleasing in appearance and can be supplied in smooth hot galvanized cast iron or cast bronze. Lettering or an insignia can be cast on each door to indicate the interior equipment or the name of the authority: "State Highway Dept." The cylinder lock prevents improper entry into box and theft of trim. Lead gasket is one piece cut full to allow for caulking and trimming.

Installed in columns of bridges, lighting posts, tunnels, portals, signal pylons, toll houses, underpasses, bank buildings, H8200 boxes make excellent pull boxes and enclosures for cut outs, signal equipment, emergency lighting switches, relays and time switches. -

H42000 Type - Metal-Pipe Pole Bases

Cast Iron - Hot Dipped Galvanized

Lighting poles easily fabricated by combining threaded pole bases with coupled lengths of conduit or pressure pipe. Limitless variety of custom-made uprights can be erected below usual costs. Adapted to small or large quantities. Attractive design of tough cast iron; hub tapped deep for strong, locking engagement with pipe; ample junction chamber for stubbing conduit, splicing and grounding.

Lighting applications:

Parking areas, service stations, car-lots, railway platforms, yards and docks, piers, walkways.

Other applications:

Mounting for signs, signals, police and fire boxes, yard-speakers, electrical enclosures.

Bases tapped for 1/4" - 20 ground stud.